In the 1960s, the Rheem CalCor Metal Building Division built seven steel

homes in California. Each home cost approximately $15,000 ($160,000 in today's dollars)

to build—and in 2022, one of those homes sold for $1.6 million

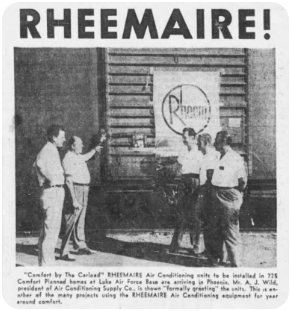

To market the Rheemaire, Rheem once hosted ice-melting contests in Texas.

Customers guessed how long it would take 40 tons of ice to melt—down to the second—and

the person with the most accurate guess would win a Rheemaire system.

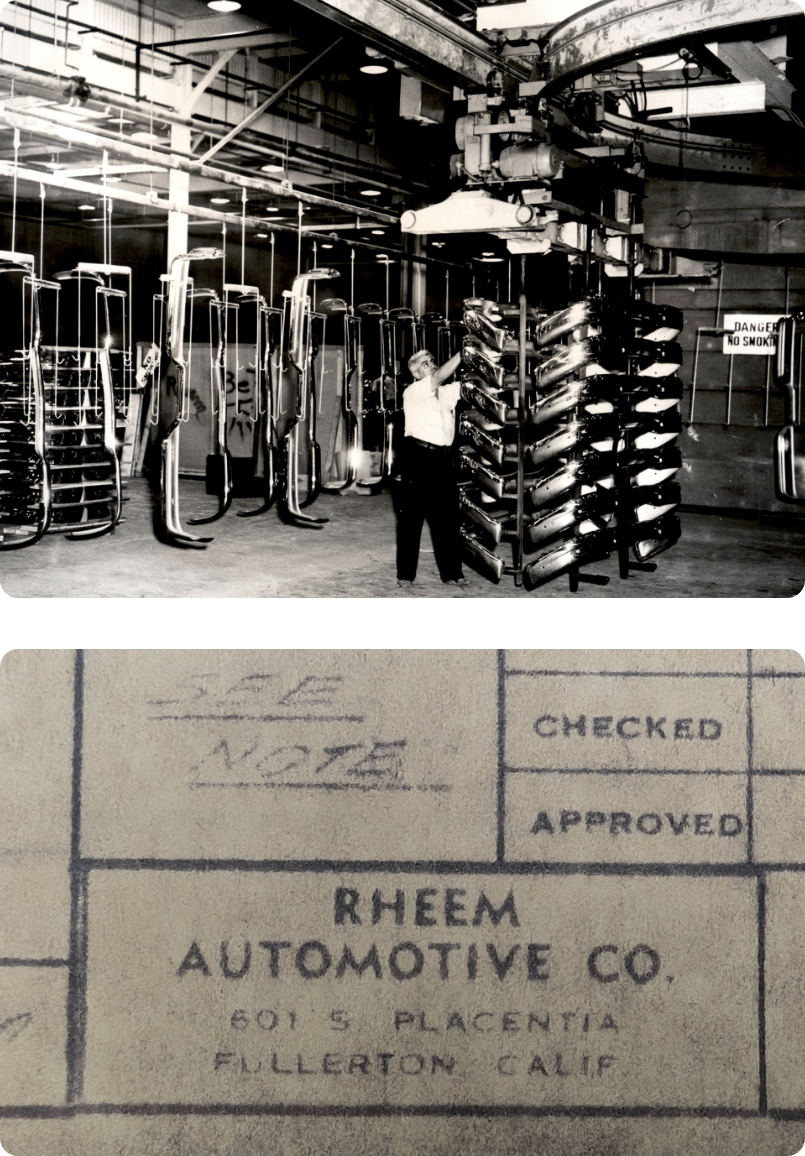

The former Rheem Superior division made everything from electrical panels

to pressurized trucks and trailer tanks to diving bells.

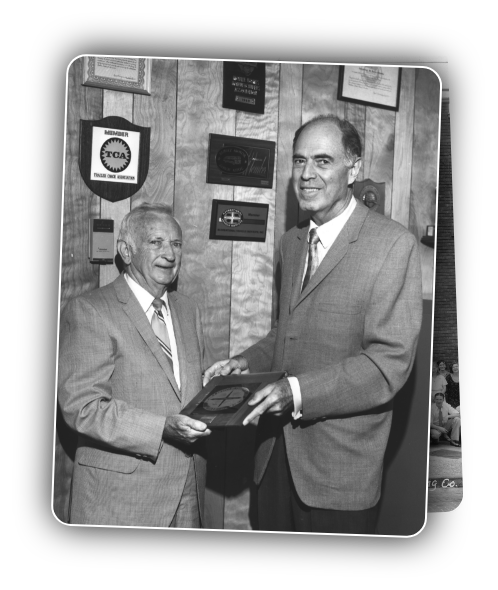

In 1942, the United States Navy bestowed Rheem's Richmond and Newark plants

with the coveted Navy E Award—the highest of Navy honors—for outstanding

production of defense materials.

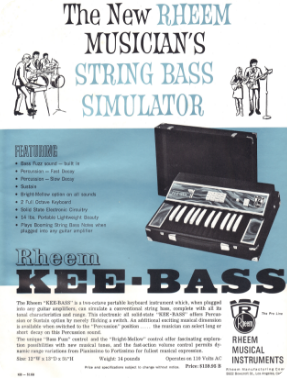

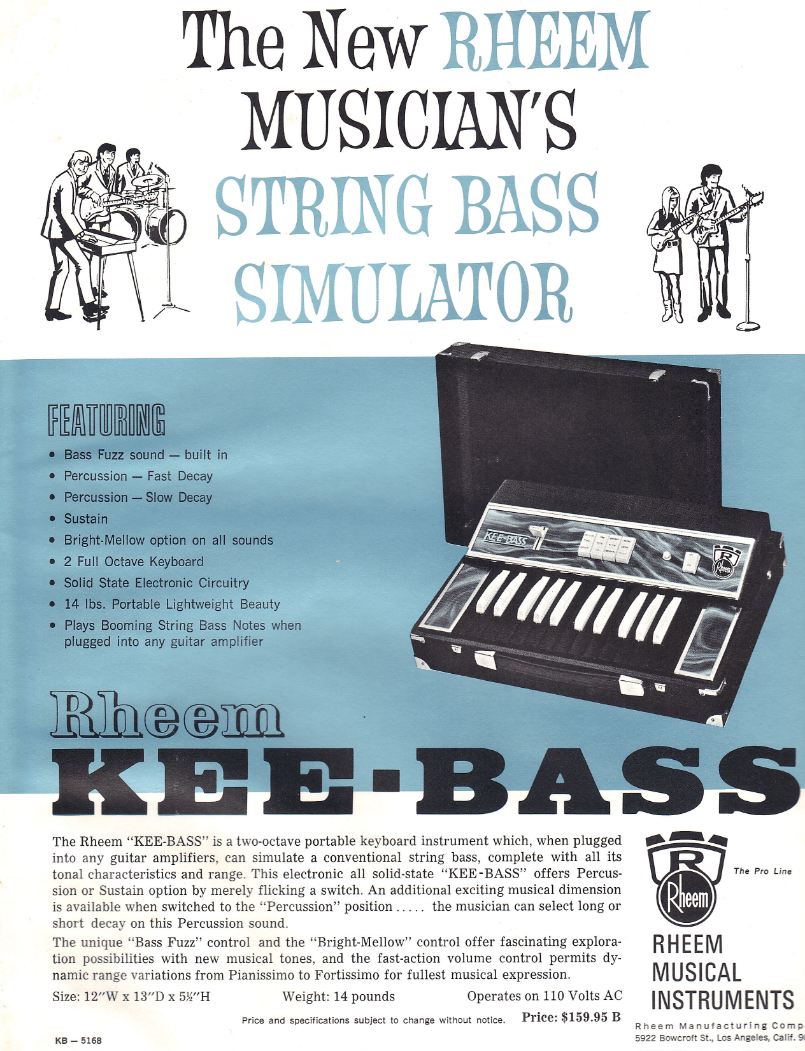

In the 1960s, Rheem developed the Kee Bass, a combination of an organ and

bass synthesizer. You can see a Rheem Kee Bass in action in the music video "Whip It,"

by DEVO.

The next time you buy a whole turkey or chicken, check out the little metal

clip at the top of the package and the loop at the end of the netting that makes it

easier to carry. This Tipper Tie is a Rheem innovation.

Rheem MEA (Middle East and Africa), has a Ministry of Fun that plans

parties to celebrate holidays, runs a soccer league and organizes group activities such

as laser tag and paddling in the mangroves outside Dubai.

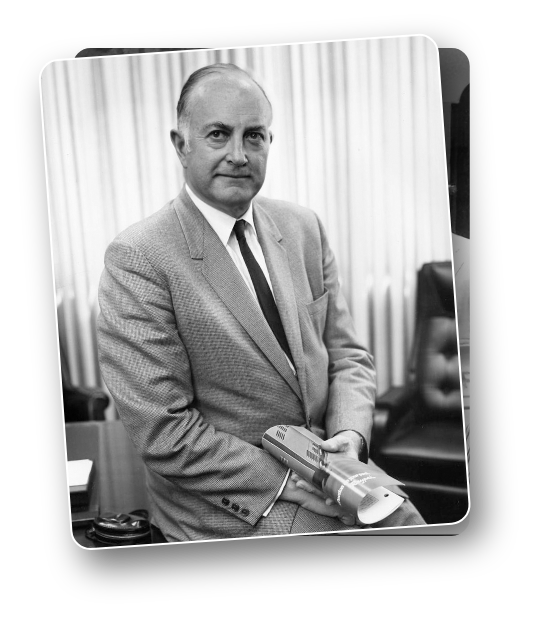

Donald Rheem developed an unincorporated community in California which was

named after him—Rheem, California.

In 1938, Donald Rheem purchased Moran Mansion in the San Juan Islands

located between Washington State and Vancouver Island, Canada. His wife, Alice, is said

to haunt the mansion to this day and is known as The Lady in Red. She is characterized

as a bit mischievous, but harmless.

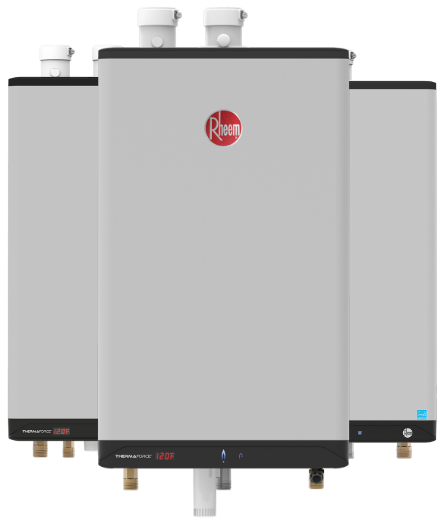

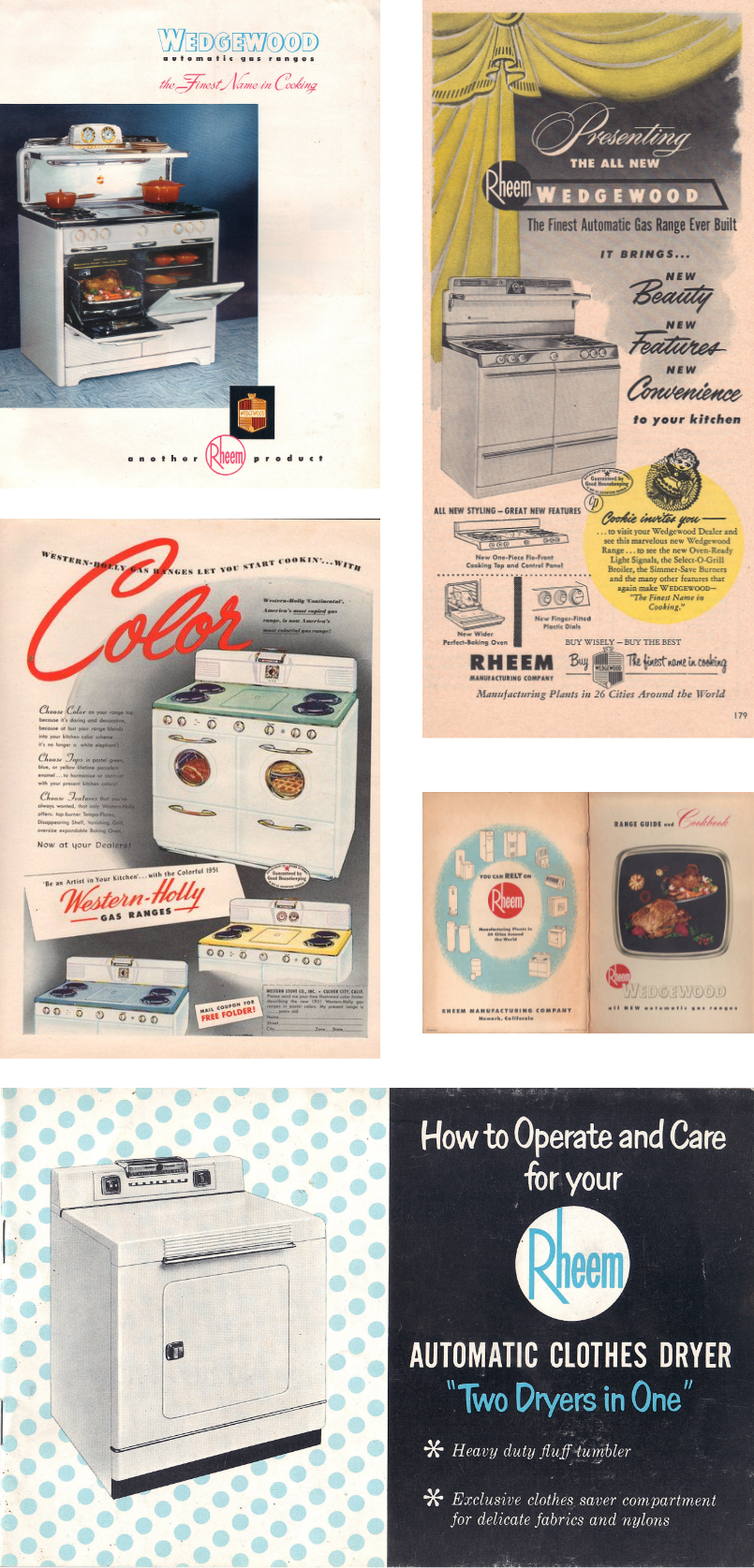

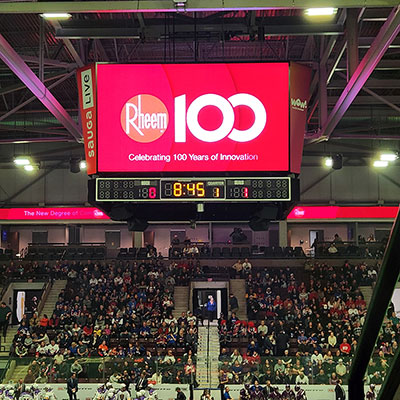

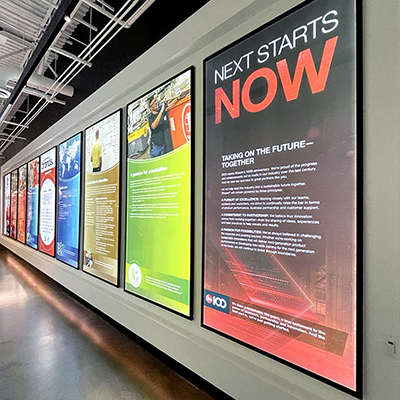

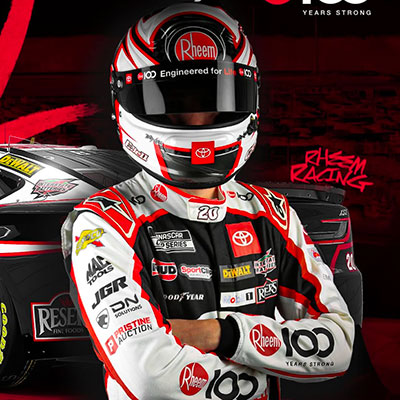

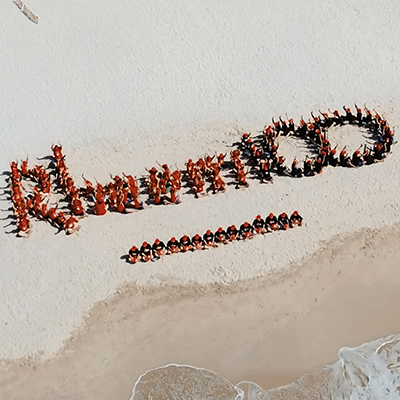

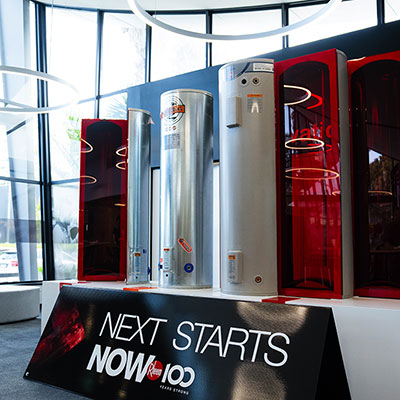

For 100 years, Rheem has been a leader in product innovation.

For 100 years, Rheem has been a leader in product innovation.

1931

1931